Breaking News

Popular News

Enter your email address below and subscribe to our newsletter

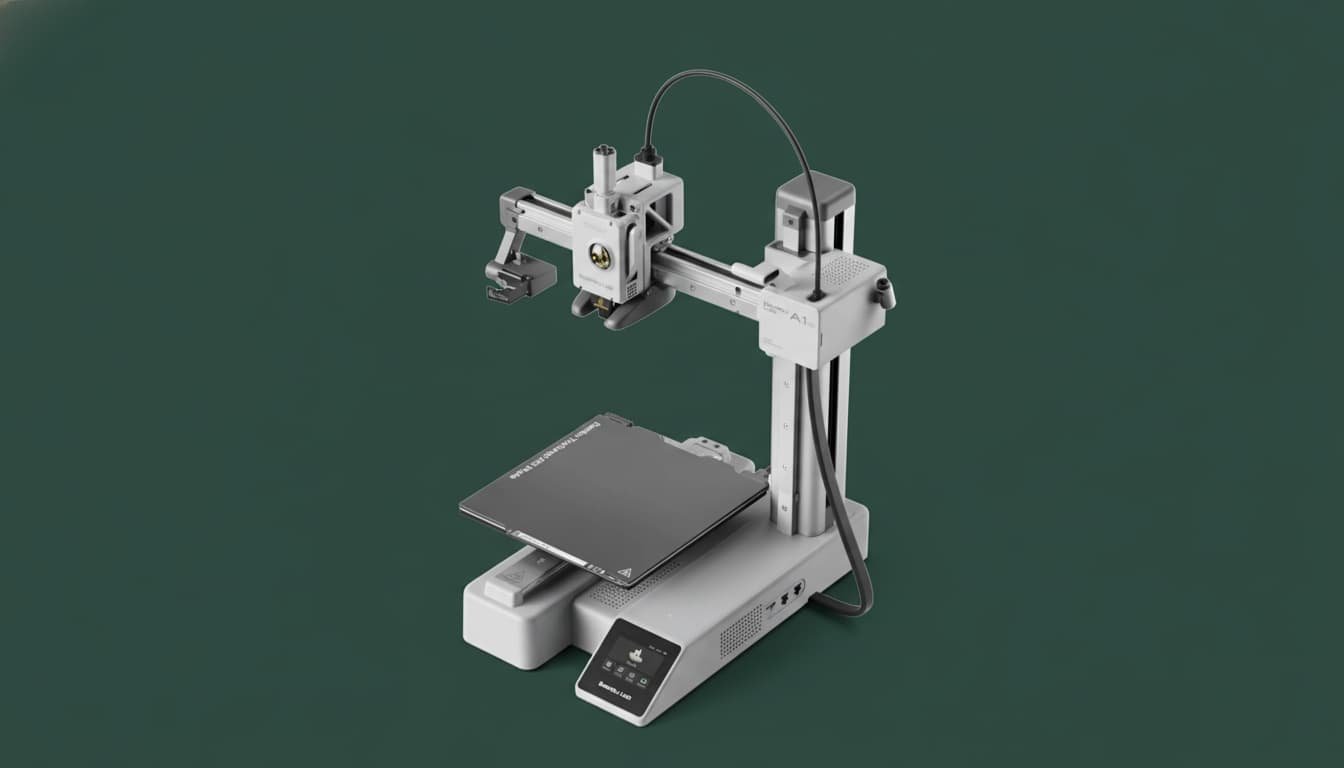

Desktop 3D printing has evolved into an accessible, high-impact tool for creating physical solutions on demand. From cable management and PC brackets to racing simulator accessories and display holders, the ability to model and produce functional components immediately has reshaped how creators approach small engineering problems. The Bambu Lab A1 Mini enters this landscape as the smallest and most affordable model in Bambu Lab’s ecosystem, offering a compact build volume paired with refined speed, software intelligence, and usability that scale down remarkably well from the flagship X1 Carbon.

With a 180 mm³ build capacity, the A1 Mini accommodates the majority of day-to-day prints—structural brackets, vents, mounts, enclosures, and decorative items. Its bedslinger motion system and compact footprint make it suitable for desks and workstations where space is limited, yet its performance feels closer to high-end CoreXY hardware than a typical entry-level printer.

Despite its size and pricing tier, the A1 Mini features a surprisingly premium construction. Its steel and aluminum frame increases stability, while its clean, lab-like aesthetic allows it to blend naturally into modern setups. A built-in camera adds remote monitoring capabilities, offering a crisp resolution though at a lower frame rate than higher-tier Bambu models.

Performance specifications align closely with the X1 Carbon in several areas. The nozzle reaches the same maximum temperature, the heated bed reaches 80°C, and the toolhead speed is identical. Acceleration is reduced to about half of the flagship model, but in real-world printing this still translates to fast, responsive movement. Nozzle swap flexibility—from 0.2 mm for detail to 0.8 mm for rapid extrusion—extends the versatility of a small machine.

Unlike the X1 or P1 series, the A1 Mini lacks an enclosure. However, early testing shows that many materials remain printable even in open-air conditions, especially PLA and PETG. Alongside automatic bed leveling, flow dynamics calibration, and nozzle wiping, the printer prepares itself quickly and reliably at the start of each job.

A major contributor to Bambu Lab’s growing popularity is the clarity and reliability of its slicer software. Bambu Studio simplifies complex settings through highly optimized presets tuned for the company’s filaments. Users drop in a model, apply auto-orientation, choose the A1 Mini profile, select a build plate and material, and define the desired print quality.

High-quality modes prioritize thin layer heights and slower speeds for near-flawless detail, though they significantly extend print time. Mid-tier settings such as 0.12 mm or 0.16 mm layer heights offer an optimal balance for most functional prints.

For objects with overhangs, the slicer’s auto-support generation works well, and advanced adjustments improve output consistency. Enabling “avoid crossing walls” reduces the chance of seam artifacts, while adjusting the wall order to inner–outer–inner produces cleaner exterior surfaces.

While the A1 Mini does not include the X1 Carbon’s micro-LiDAR sensor for automated first-layer inspection, careful manual observation of the initial layer is generally sufficient. Once past that stage, print reliability is excellent.

PLA prints showcase the A1 Mini at its finest. The machine is exceptionally quiet—quiet enough to place on a desk without distraction—and its speed remains one of its defining strengths. Layer consistency, seam management, and surface finish rival those of higher-end printers. Structural prints such as pump reservoir brackets and airflow vents exhibit tight tolerances and clean walls, even when printed at moderate speeds and only 10% infill.

PETG presents no difficulty for the A1 Mini, provided the filament is properly dried. Transparent and translucent materials reveal more visible layer lines due to material properties rather than printer limitations. Surfaces remain smooth and free of major defects. Users must take extra care with PETG storage, as it absorbs moisture rapidly—something that affects print quality across all machines.

Until Bambu Lab’s AMS HT system becomes compatible with the A1 series, a third-party filament dryer remains necessary for maintaining PETG performance.

Nylon composites and other engineering-grade filaments require higher strength and elevated temperature performance. While technically unsupported in standard profiles, these materials can be printed after upgrading to a hardened nozzle. Custom profiles—borrowing temperature and flow settings from the larger A1 or X1 models—allow experimentation.

Humidity again plays a crucial role. Moisture-rich nylon produces stringing, dots, and surface artifacts regardless of printer capability. With proper drying and environmental control, the A1 Mini can produce functional nylon-based components, though not with the polished finish achieved by an enclosed high-end system.

ABS, however, remains outside the practical limits of the A1 Mini. Without an enclosure, prints suffer from severe warping, layer separation, and VOC exposure concerns. For ABS users, enclosed printers remain the more reliable option.

The A1 Mini proves surprisingly capable across a range of materials. PLA prints are consistently exceptional. PETG and nylon composites are achievable with environmental controls. Users needing stronger or heat-resistant parts may still prefer the P1S or X1 paired with an AMS2 Pro for dried, heated filament storage, but for most everyday prints, the A1 Mini offers an efficient and cost-effective platform.

Its only notable inconvenience is filament loading, which involves manually extruding until the new filament appears through the nozzle. While minor, it is the kind of small workflow improvement that could be refined in future iterations.

Overall, the combination of high print quality, quiet operation, thoughtful software, and compact design makes the A1 Mini one of the most compelling entry-level machines in the market. For users who do not require large-format prints or extreme material performance, it delivers exceptional value and a remarkably polished printing experience.